Introducing Juwon Robotics, a specialized company in robot automation that leads the future of manufacturing.

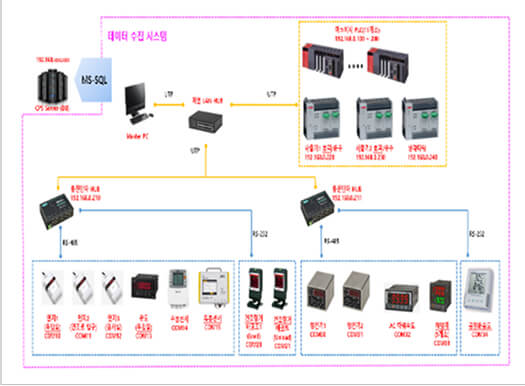

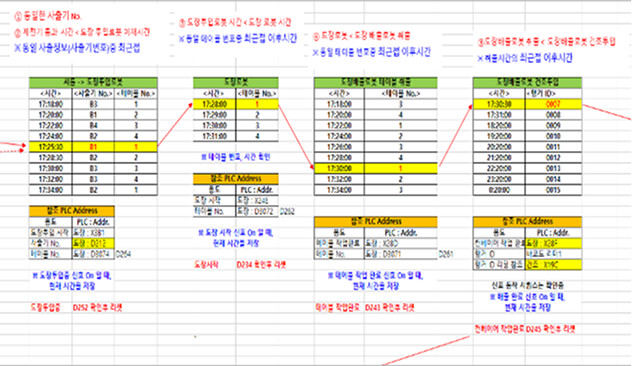

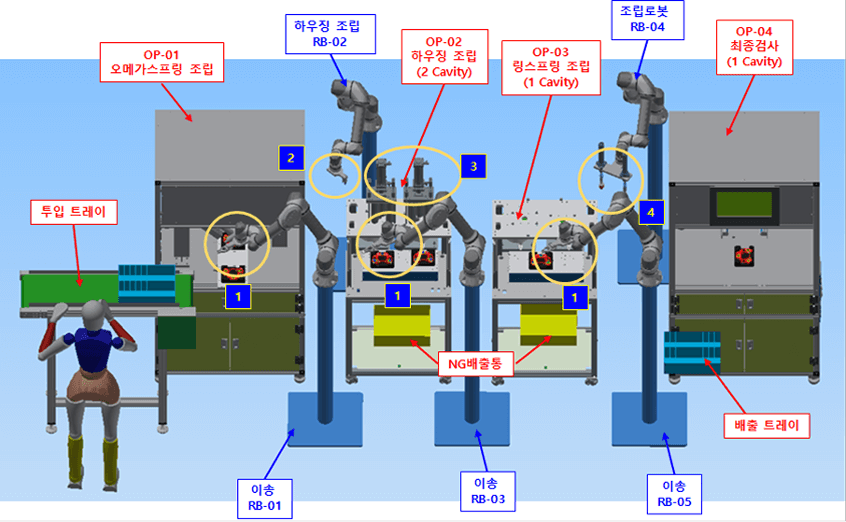

Project for Company 'I' in Gumi-si, Gyeongbuk

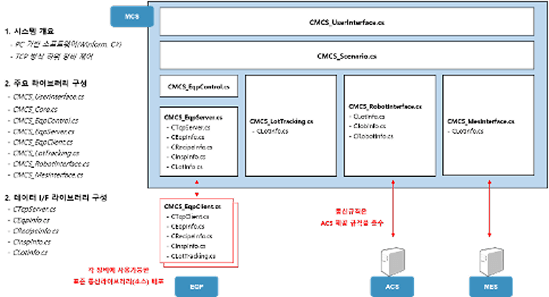

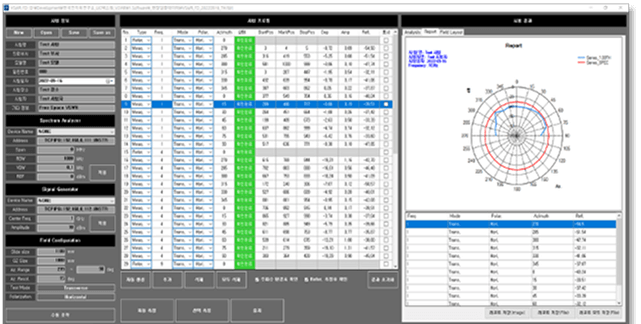

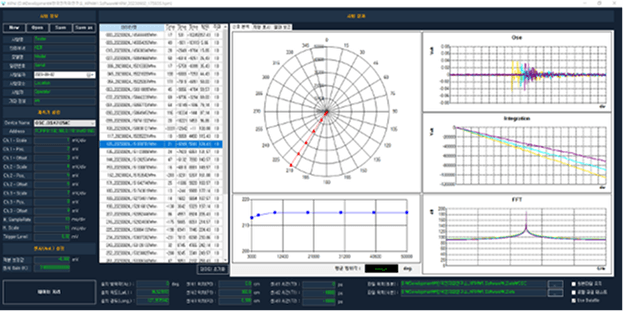

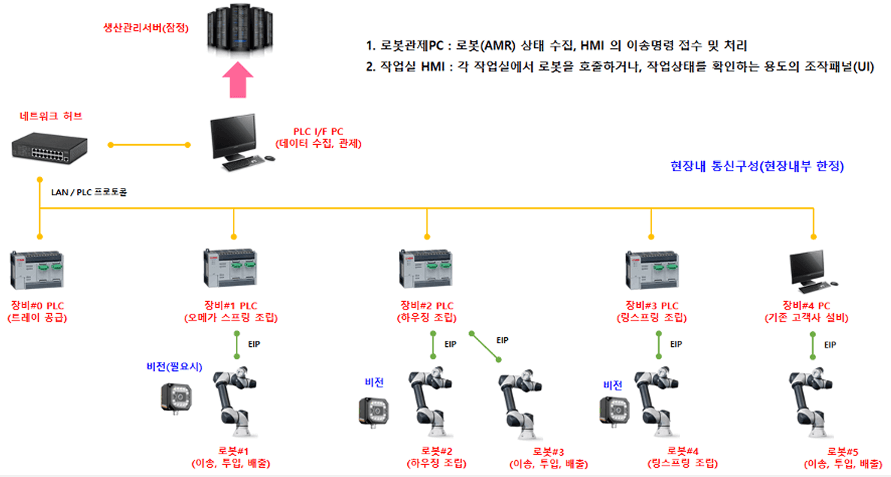

Established a data network (Hard-Wiring) between each equipment unit and the data collection server.

Collected, sorted, and processed key production information, then transmitted it to a higher-level integrated database (DB).

Designed and implemented a data flow for process information tracking (LOT Tracking) of manufactured goods.

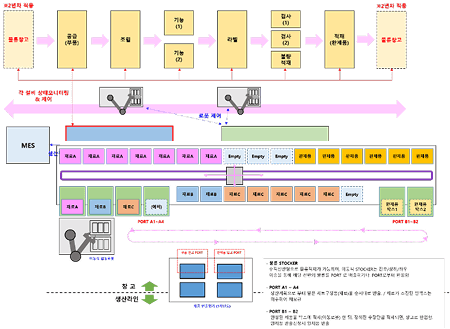

Project for Company 'A' in Daegu

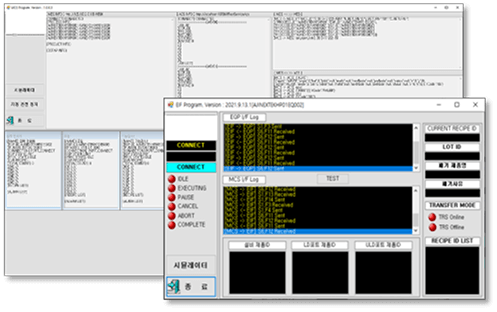

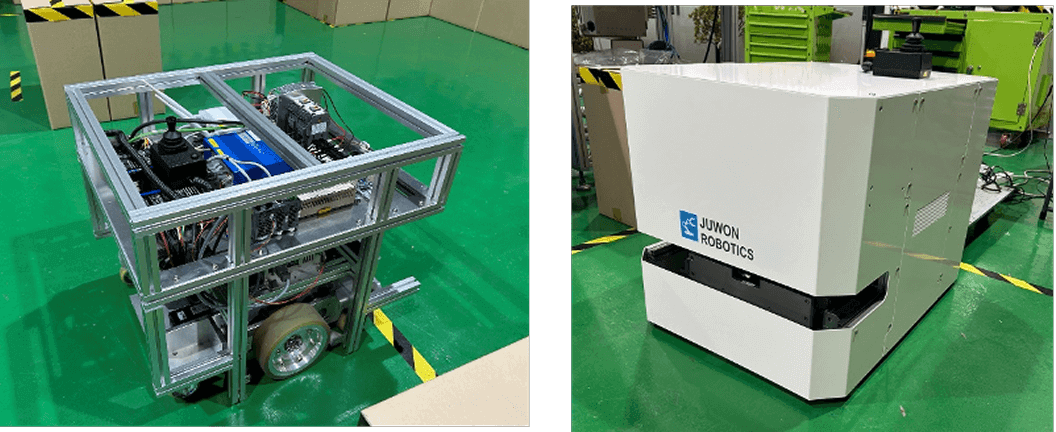

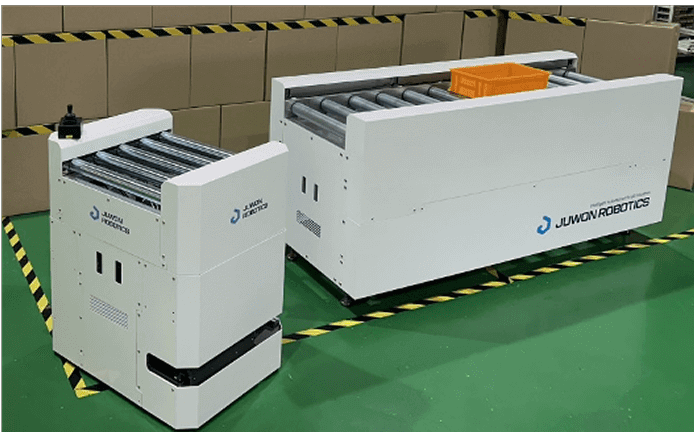

Logistics transfer management and equipment interface for AGV-applied automation lines

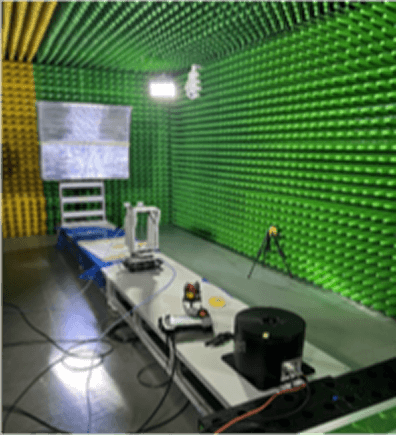

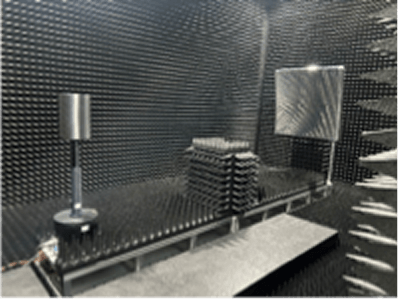

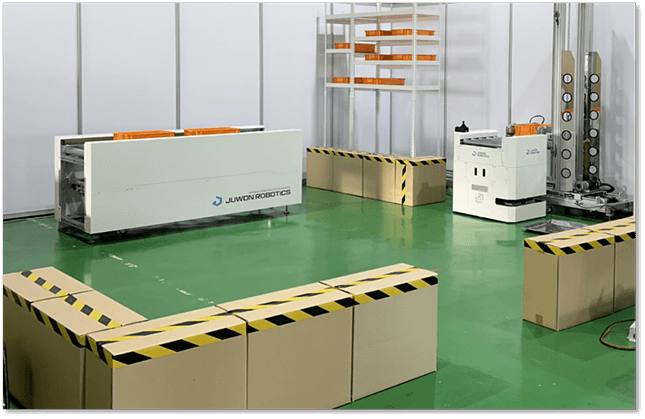

Implementation of a logistics environment for customer promotion and in-house testing

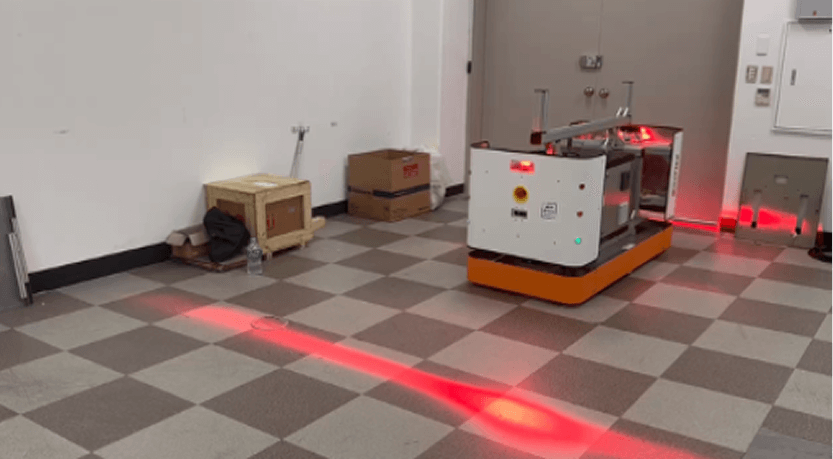

Enables integrated testing of process operation models for Autono-mous Mobile Robots (AMR).

Integration of interfaces between various unit facilities within the process.

Establishment of a test environment for AMR logistics transport and integrated control.

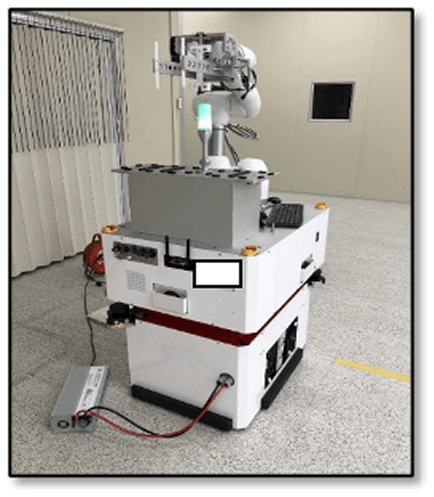

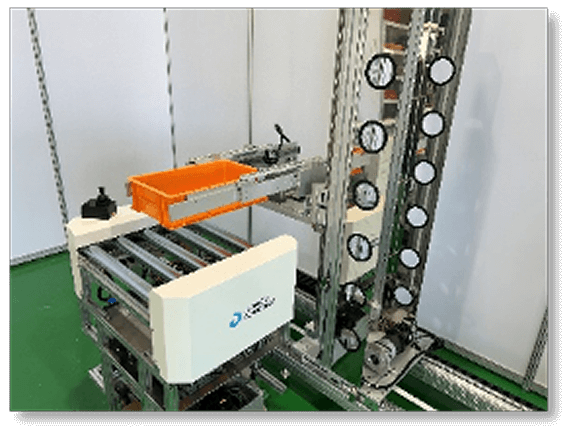

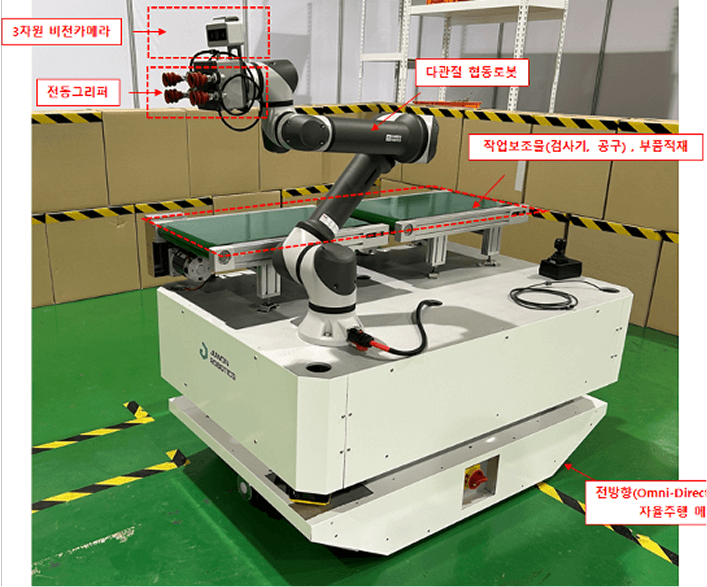

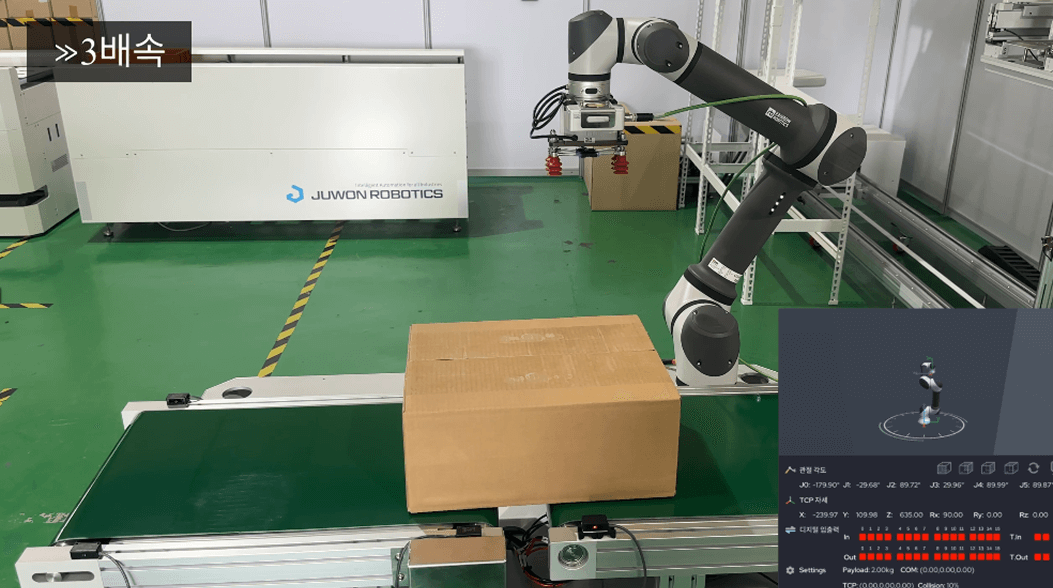

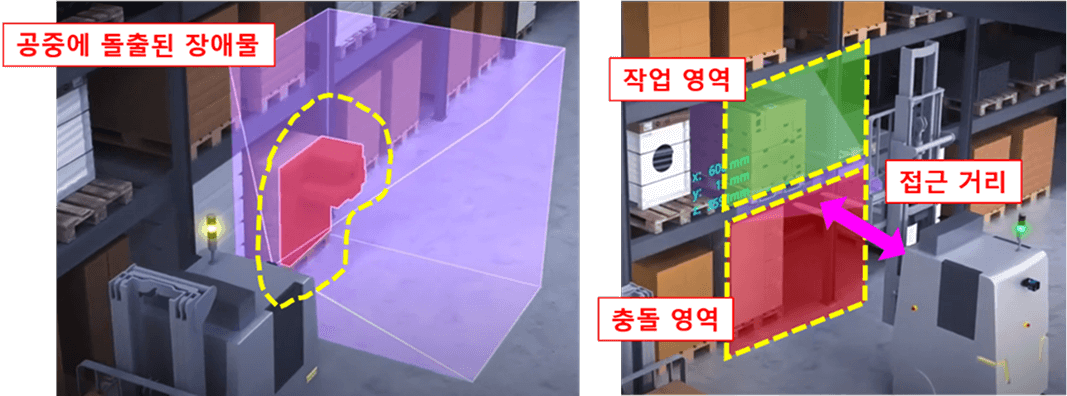

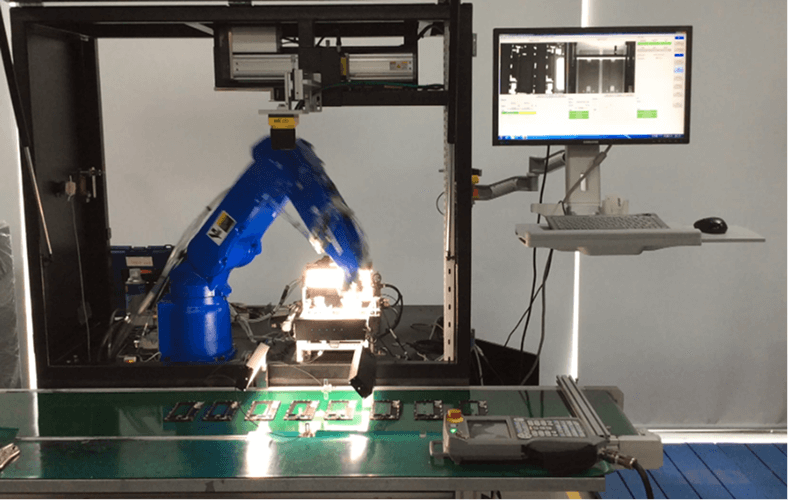

Development of an autonomous mobile collaborative robot applicable to autonomous manufacturing and flexible production environments

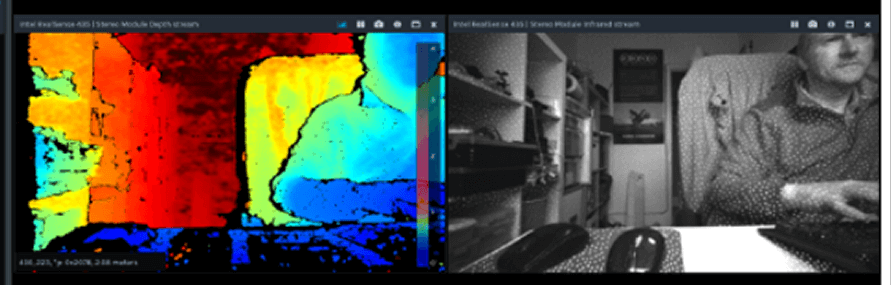

Omnidirectional movement mechanism / Linkage with 3D vision based multi-joint collaborative robots

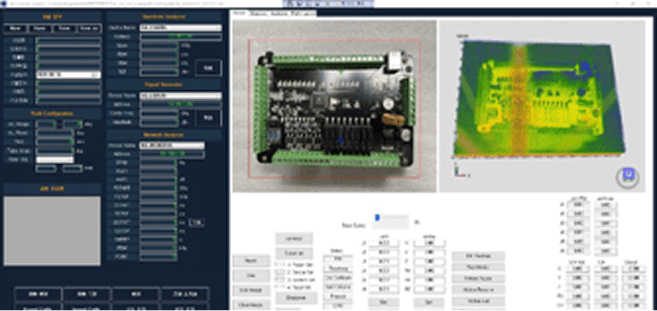

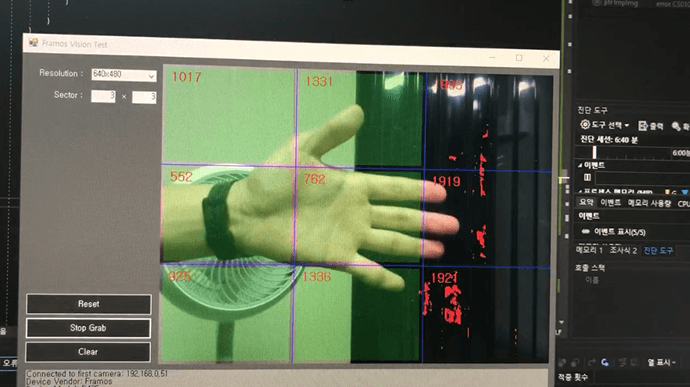

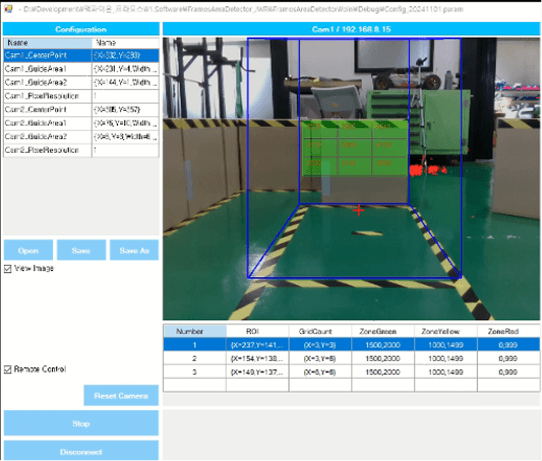

Image Processing I/F (Interface) Software for a Mobile Robot's Safety Detection Range During Operation

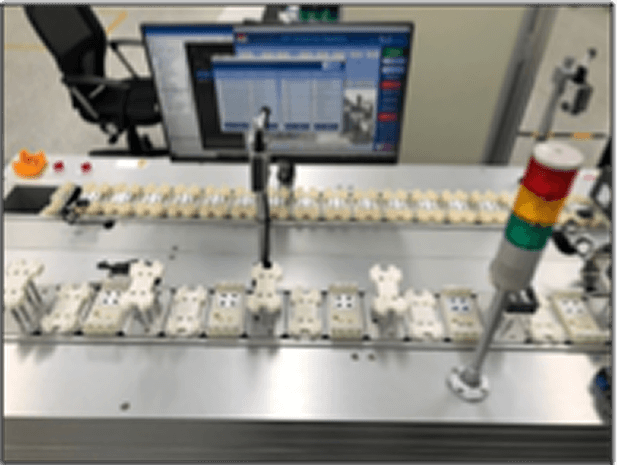

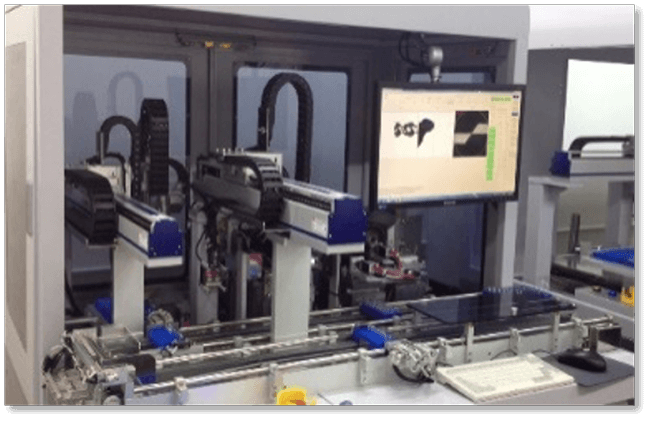

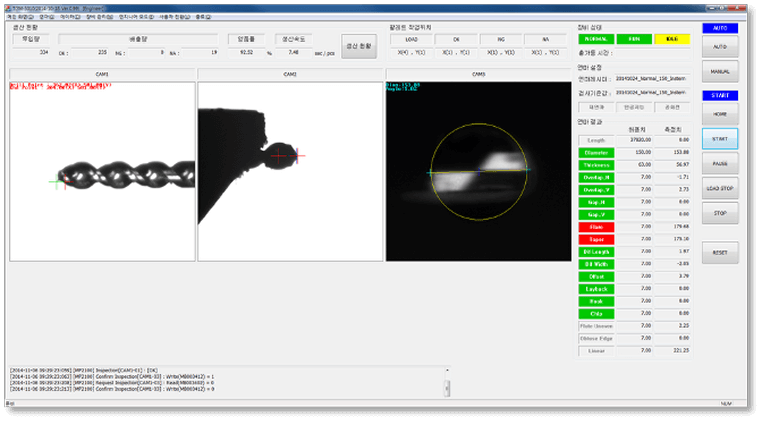

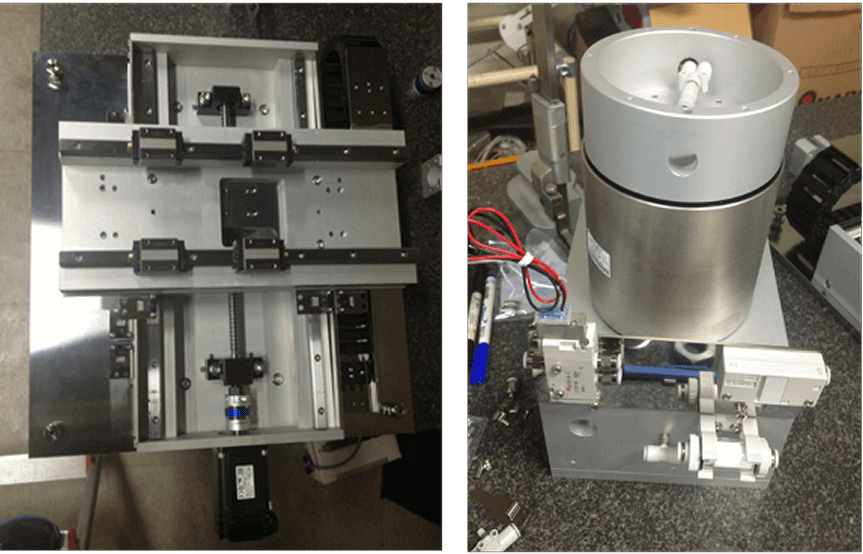

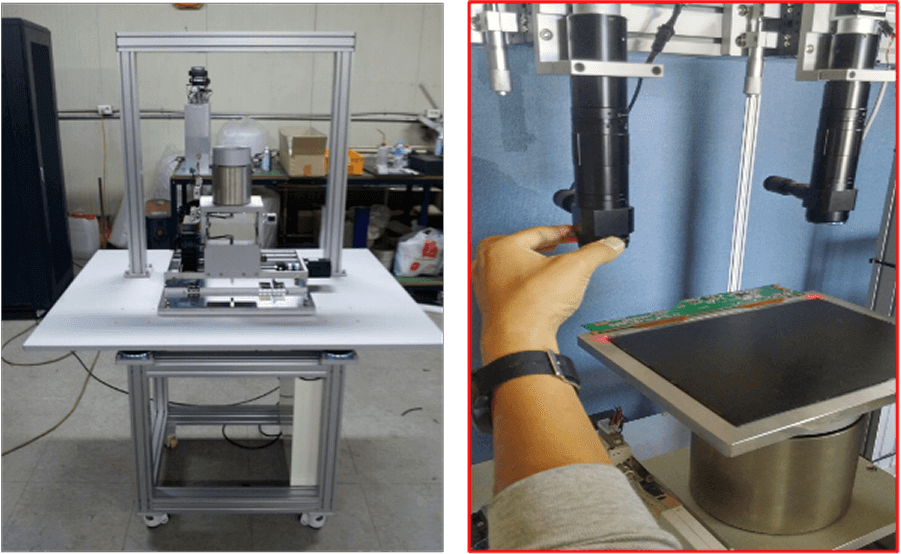

Development of PC-based Inspection/Control Systems

Supplied to affiliates of Company 'Y' (Korea) and FOXCONN (China)

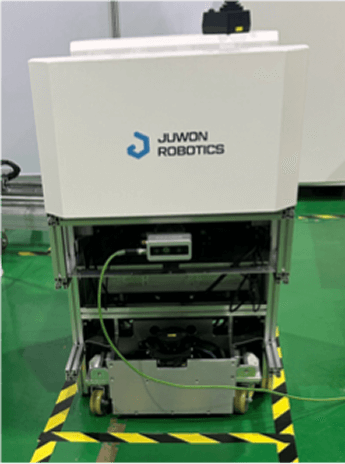

Multi-purpose industrial Autonomous Mobile Robot applicable to small and medium-sized manufacturing sites

Ensures technical reliability by using a commercial navigation controller (ANT lite+ by Bluebotics), providing easy integration with industrial interfaces and satisfying industrial safety regulations.

Technology ;

The great growing engine of change